1. Why do Medium and Large Buyers must Perform Factory Audits?

- Secure your orders and future cooperation

- Find an appropriate factory for mass production

- Let suppliers take on more safety, social responsibility, environmental protection, labor laws, etc.

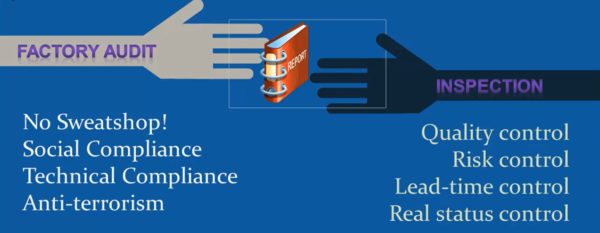

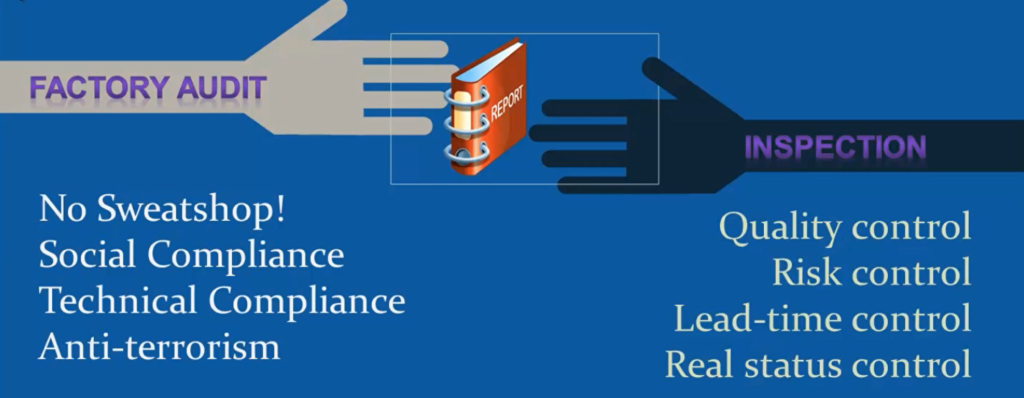

2. The Key Points of Factory Audit and Product Inspection

2.1 Key Points of Factory Audit

- No Sweatshop(Comply with local labor laws)

- Social Compliance (Meet local environmental assessment requirements)

- Technical Compliance

- Anti-Terrorism

2.2 Key Points of Inspection

- Quality Control

- Risk Control

- Lead-Time Control

- Real Status Control

3. Principles of Factory Audit and Inspection

3.1 Factory Audit

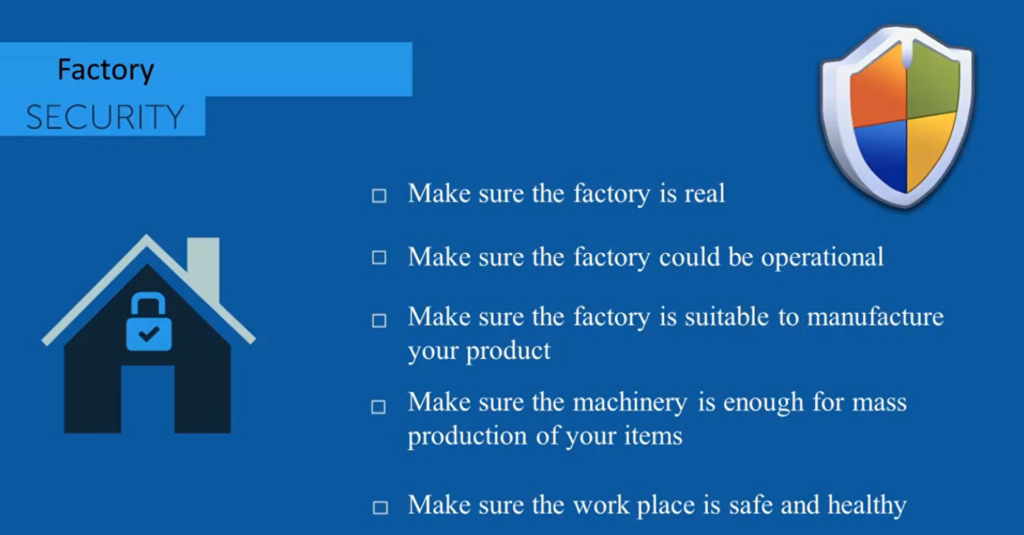

3.1.1 Security

- Make sure the factory is real

- Make sure the factory could be operational

- Make sure the factory is suitable to manufacture your product

- Make sure the machinery is enough for mass production of your items

- Make sure the workplace is safe and healthy

3.1.2 Social Compliance – (ZERO TOLERANCE)

-1024x494.png)

- No Child Labor

- No Sexual Harassment

- No Gender Discrimination

- No illegal Actions

- C-TPAT Compliance

3.1.3 Management Security

- Fire Safety Certificate

- Environment Protection Certificate(Local EIA certificate)

- Personnel Safety Management(Visitor registration? Cameras? Staff Dormitory?)

- Employment Management

3.2 Recap of Inspection

- Make sure the items are strictly according to the request and the contract

- Risk control and a series of steps before balancing payment

- Keep your eyes on the factory to get the real status of production, quality, lead time, etc.

3.2.1 Pre-Production Inspection

- The focus is on inspection of raw material procurement, semi-finished product preparation, and capacity arrangement

- Ensure adequate preparation

- Make sure the raw materials are not fake or substandard

- Note: You must get the Pre-Inspection Pass to continue the production process

3.2.2 DUPRO(During Production)/ Inline Inspection

- It will generally be scheduled at 30% completion (depending on the actual)

- Make sure the quality of the finished product meets the requirements

- Make sure that production can be completed before the delivery date

- Large orders with high value may have multiple DUPRO inspections

3.2.3 Final Inspection/ Pre-Shipment Inspection

- Usually when the goods are 100% complete and the packaging is 80% complete

- Some customers require the inspector to supervise the loading during the final inspection

- Normally, please agree on a final inspection date at least 7 days in advance

Conclusion

In short, Factory audit and product inspection have different purposes, and, in the negotiation of cooperation for some bulk goods, factory inspection is often the last step before cooperation, while goods inspection is necessary for almost every B2B wholesale order. If you have any questions about imported furniture, feel free to contact me, I also hope you can follow our Blog, I will continue to export this part of the experience.